Tread Marking System

MOQ : 1 Set

Tread Marking System Specification

- Marking Speed

- 7000 mm/s

- Marking Area

- 200 mm x 200 mm

- Condition

- New

- Laser Type

- Fiber Laser

- CNC

- Yes

- Cooling Mode

- Air Cooling

- Control Software

- SmartMark

- Accuracy

- 0.01 mm

- Power

- 50W

- Dimensions

- 700 mm x 500 mm x 1450 mm

- Safety Features

- Emergency Stop & Enclosed Laser Head

- Supply Voltage

- 220V / 50Hz

- Ambient Temperature

- 5°C to 40°C

- Marking Depth

- 0.1 mm - 2 mm

- Laser Wavelength

- 1064 nm

- Tread Pattern Recognition

- Integrated OCR & Pattern Match

- Display

- Touch Screen Control Panel

- Interface

- USB / Ethernet

- Automation

- Automatic Feeding & Ejection

- Application

- Tyre Manufacturing, Automotive Workshops

- Material Compatibility

- Rubber, Synthetic Compound

Tread Marking System Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Month

- Delivery Time

- 15 Days

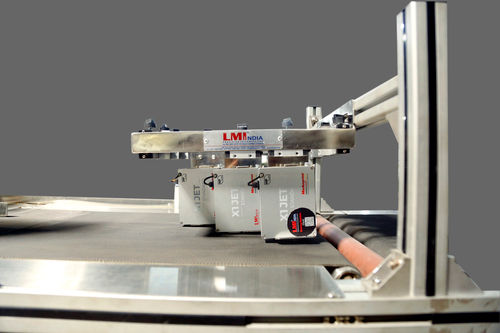

About Tread Marking System

Jump on the future of tire identification with the Tread Marking System, designed for commanding performance in automotive workshops and tyre manufacturing plants across India. With a robust supply voltage of 220V/50Hz and advanced connectivity via USB/Ethernet, this system delivers first-rate results for marking rubber and synthetic compounds. Fresh innovations, such as integrated OCR & pattern matching, optimum safety features, and a fiber laser at 1064 nm, guarantee accurate, cost-effective, and secure operations. Automatic feeding and ejection streamline workflow for distributors, exporters, suppliers, and manufacturers.

Optimum Solution for Plant Application

The Tread Marking System is a commanding asset used in tyre manufacturing plants and automotive workshops for tread identification and quality assurance. Its precise marking depth, efficient feeding and ejection, and material compatibility with rubber and synthetic compounds offer plant operators a first-rate advantage. This system is employed as a reliable, cost-effective solution to meet demanding production schedules and is suited for suppliers and traders seeking an edge in the competitive market.

Sample Policy and Packaging Details

Upon arrival, clients can request samples to evaluate the systems fresh capabilities before committing to full supply. Shipped securely with robust, industrial-grade packaging, the Tread Marking System reaches you in optimum condition. Sample units are available as part of our sample policy to ensure clients experience the first-rate performance and accuracy firsthand. Distributors and wholesalers benefit from timely supply and clear packaging details for inventory management.

Optimum Solution for Plant Application

The Tread Marking System is a commanding asset used in tyre manufacturing plants and automotive workshops for tread identification and quality assurance. Its precise marking depth, efficient feeding and ejection, and material compatibility with rubber and synthetic compounds offer plant operators a first-rate advantage. This system is employed as a reliable, cost-effective solution to meet demanding production schedules and is suited for suppliers and traders seeking an edge in the competitive market.

Sample Policy and Packaging Details

Upon arrival, clients can request samples to evaluate the systems fresh capabilities before committing to full supply. Shipped securely with robust, industrial-grade packaging, the Tread Marking System reaches you in optimum condition. Sample units are available as part of our sample policy to ensure clients experience the first-rate performance and accuracy firsthand. Distributors and wholesalers benefit from timely supply and clear packaging details for inventory management.

FAQs of Tread Marking System:

Q: How does the Tread Marking System ensure optimum accuracy during marking?

A: The system utilizes SmartMark control software combined with a fiber laser at 1064 nm and integrated OCR & pattern match technologies, delivering an accuracy of 0.01 mm for consistent, first-rate tread marks.Q: What is the process for obtaining a sample unit and how is it shipped?

A: Clients may request sample units before purchase. Samples are shipped securely in robust packaging to ensure arrival in excellent condition, enabling buyers to test and confirm system performance prior to order placement.Q: Where can the Tread Marking System be used effectively?

A: This system is designed for tyre manufacturing facilities, automotive workshops, and any environment requiring commanding identification of rubber or synthetic compound treads.Q: When is it recommended to use the Tread Marking System for pattern recognition?

A: Use the system during the tyre marking process for precise tread pattern recognition and quality control, thanks to its integrated OCR and pattern matching functions.Q: What are the safety features integrated into the Tread Marking System?

A: Safety is ensured through an enclosed laser head and emergency stop features, preventing unauthorized exposure and supporting safe operation in any manufacturing setting.Q: How does automation benefit plant operators using this system?

A: Automatic feeding and ejection accelerate workflow, reduce manual handling, and enhance overall productivity, making operations more cost-effective and streamlined for both suppliers and manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Marking Systems Category

Laminate Marking

Price Range 12000.00 - 27000.00 INR

Minimum Order Quantity : 1 Set

Accuracy : 0.01 mm

CNC : Yes

Condition : New

Control Software : EZCAD

Laminate Marking System

Price Range 7000.00 - 22000.00 INR

Minimum Order Quantity : 1 Set

Accuracy : 0.01 mm

CNC : Yes

Condition : New

Control Software : EZCAD

Thermal Marking Machine

Price Range 6999.00 - 11000.00 INR

Minimum Order Quantity : 10 Sets

Accuracy : 0.01 mm

CNC : Yes

Condition : New

Control Software : EZCAD

Large Character Marking Machine

Price Range 999.00 - 3500.00 INR

Minimum Order Quantity : 5 Sets

Accuracy : 0.01 mm

CNC : Yes

Condition : New

Control Software : WindowsBased Proprietary Software

Send Inquiry

Send Inquiry