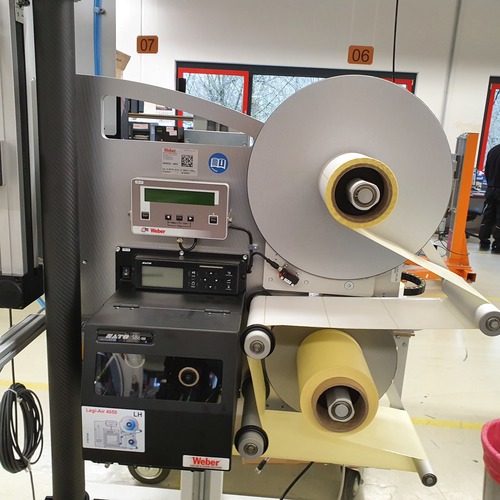

Printing & Apply System

MOQ : 1 Set

Printing & Apply System Specification

- Speed Range

- Up to 60 products/min

- Phase

- Single Phase

- Mounting Type

- Floor Mounted

- Processor Type

- Industrial Grade Processor

- Load Capacity

- Up to 30 kg

- Cable Length

- 2 meters

- Application

- Label Printing and Application

- IP Rating

- IP54

- Sensor Type

- Photoelectric Sensor

- Frequency

- 50/60 Hz

- Drive Type

- Servo drive

- Features

- High Precision, Easy Installation

- Weight

- Approx. 85 kg

- Remote Control

- Yes

- Automation Grade

- Automatic

- Control Type

- PLC Based

- Screen Size

- 7 inch Touch Screen

- Connectivity Type

- Ethernet, USB

- Material

- Stainless Steel

- Power

- 150 W

- Voltage

- 230 V AC

- Label Roll Diameter

- Max. 300 mm

- Backup Battery

- Yes (for controller)

- Label Application Accuracy

- ±1 mm

- Power Supply Protection

- Overload and Short Circuit

- Compatible Label Materials

- Paper, Polyester, Polypropylene

- Communication Protocols

- TCP/IP, RS232, Modbus

- Print Resolution

- 300 dpi

Printing & Apply System Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Month

- Delivery Time

- 15 Days

About Printing & Apply System

Our Label Print & Apply Systems are quick, reliable and trouble free for broad range of products and applications.

As an expert we know 120 ways of label application including RFID and do supply your application and get a perfect solution.

Precision Meets Durability

Constructed from stainless steel and equipped with an industrial-grade processor, this system ensures precise label application with an accuracy of 1 mm, even in challenging environments. The servo-driven mechanism and photoelectric sensors provide reliable operation, delivering consistent results product after product.

Efficient and Automated Operation

Designed for high-throughput applications, the automated Printing & Apply System achieves speeds of up to 60 products per minute. The 7-inch touch screen interface and PLC-based control make operation simple, while Ethernet and USB connectivity allow seamless data integration and remote management.

Reliable Safety and Convenience

This system prioritizes safety and usability, featuring built-in overload and short-circuit protection, backup battery support for uninterrupted operation, and an IP54 rating for dust and splash resistance. Easy installation, floor-mounted design, and a robust load capacity of up to 30 kg make it ideal for diverse manufacturing environments.

FAQs of Printing & Apply System:

Q: How does the Printing & Apply System ensure accurate label placement?

A: The system uses a servo drive and photoelectric sensor technology, combined with PLC-based controls, to maintain a label application accuracy of 1 mm. This ensures each label is precisely positioned on your products, even at high speeds.Q: What types of label materials are compatible with this system?

A: This system accommodates a variety of label materials including paper, polyester, and polypropylene, making it suitable for different industrial labeling requirements.Q: When should I consider using an automatic Printing & Apply System?

A: This solution is ideal when you need to increase production efficiency, improve label placement accuracy, and handle larger labeling volumes with minimal manual intervention.Q: Where is this Printing & Apply System best installed?

A: It is designed for floor mounting and can be integrated into existing production lines within manufacturing, packaging, and warehousing facilities, especially where moderate dust or water splashes may occur (IP54-rated environments).Q: What is the typical process for setting up and using the system?

A: Installation is straightforward: position the floor-mounted system, connect power (230 V AC single phase), load your label roll (up to 300 mm diameter), select settings via the 7-inch touch screen, and begin automatic operation after integrating communication protocols as needed.Q: How do the power and safety features benefit daily operation?

A: With overload and short-circuit protection, plus a backup battery for the controller, the system safeguards continuous operation and minimizes downtime, even during power fluctuations.Q: What are the primary benefits of this Printing & Apply System for businesses?

A: Key benefits include increased labeling accuracy, higher throughput (up to 60 products/min), robust construction, remote control capability, easy integration, and optimized safety for reliable, long-term performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Print & Apply System Category

Thermal Transfer Overprinting Printer/ Coder (TTO)

Price Range 22000.00 - 76000.00 INR / Set

Minimum Order Quantity : 1 Set

Send Inquiry

Send Inquiry